Capabilities

our work

PRECISION Manufacturing Services

True to its name, Extreme Precision delivers ultra-precision machining, build-to-print sub-assemblies, and AS9100-certified quality inspection services.

Since 1943, our team has produced tight-tolerance components for OEMs and Tier 1 and Tier 2 suppliers in aerospace, automotive, defense, firearms, medical, and precision tooling industries. With state-of-the-art equipment and rigorous inspection processes, we ensure accuracy, compliance, and repeatable performance with every project.

83 Years

In Business

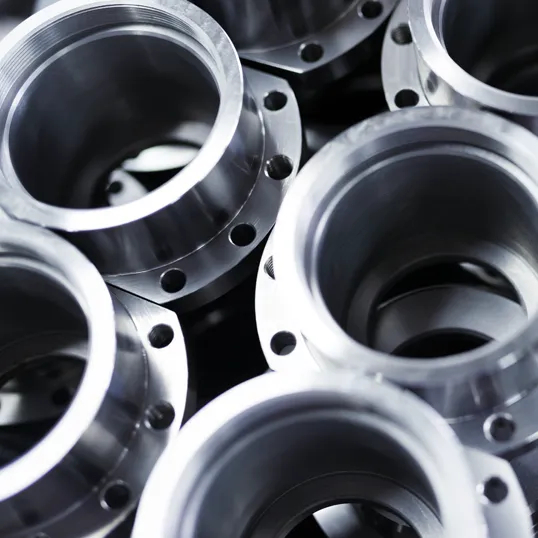

Ultra-Precision Machining

Our highly experienced team operates state-of-the-art machinery and advanced inspection technology to deliver complex parts with exceptional accuracy. Our processes are built around consistency, reliability, and attention to detail that ensures every project meets the highest standards.

±0.0001

Inch Maintainable Tolerances

Components

Custom Parts

Screw Machine Parts

Prototypes

Precision Fasteners

Custom Tooling

Test Fixtures

Hand Tools

And More

Sub-Assemblies & Manufacturing

At Extreme Precision, we go beyond individual parts to deliver complete, build-to-print sub-assemblies manufactured with the same accuracy and attention to detail as our precision components. Our experienced team specializes in small-batch production, giving you ready-to-use solutions that streamline your operations and reduce downtime.

Build-to-Print

Sub-Assemblies

Small-Batch

Production

Ready-to-Use

Components

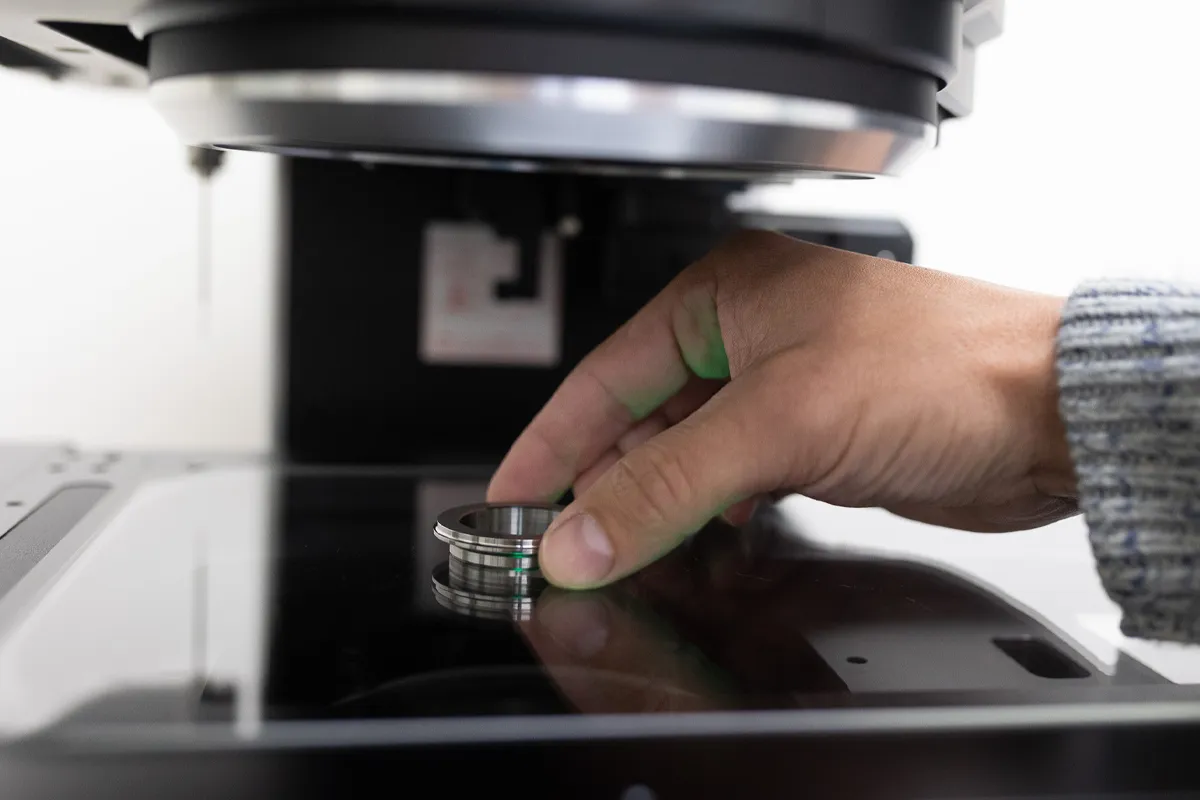

Passivation & Quality Inspection

Passivation

- Improves corrosion resistance

- Extends part lifespan and performance

- Ensures compliance with aerospace and other precision industry standards

- Provides a cleaner, more reliable finish

Certified Quality System

Our AS9100-certified process provides full traceability, process control, and accountability.

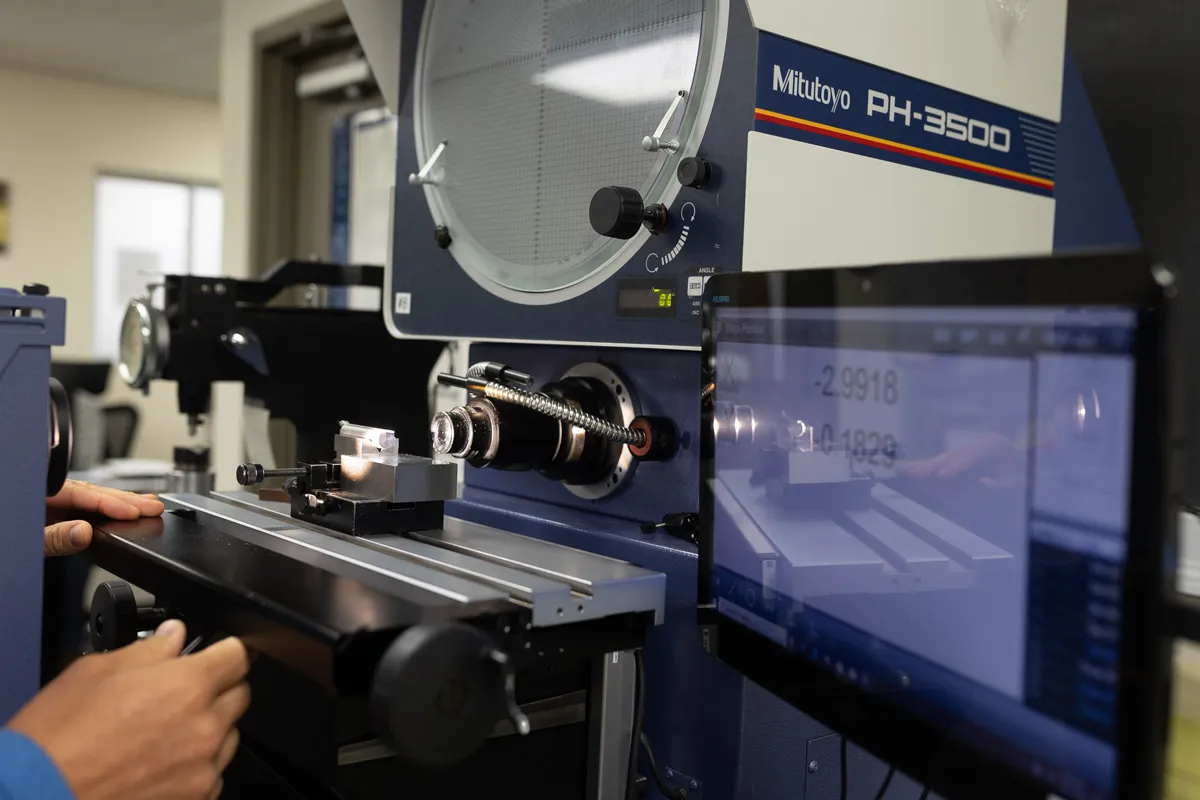

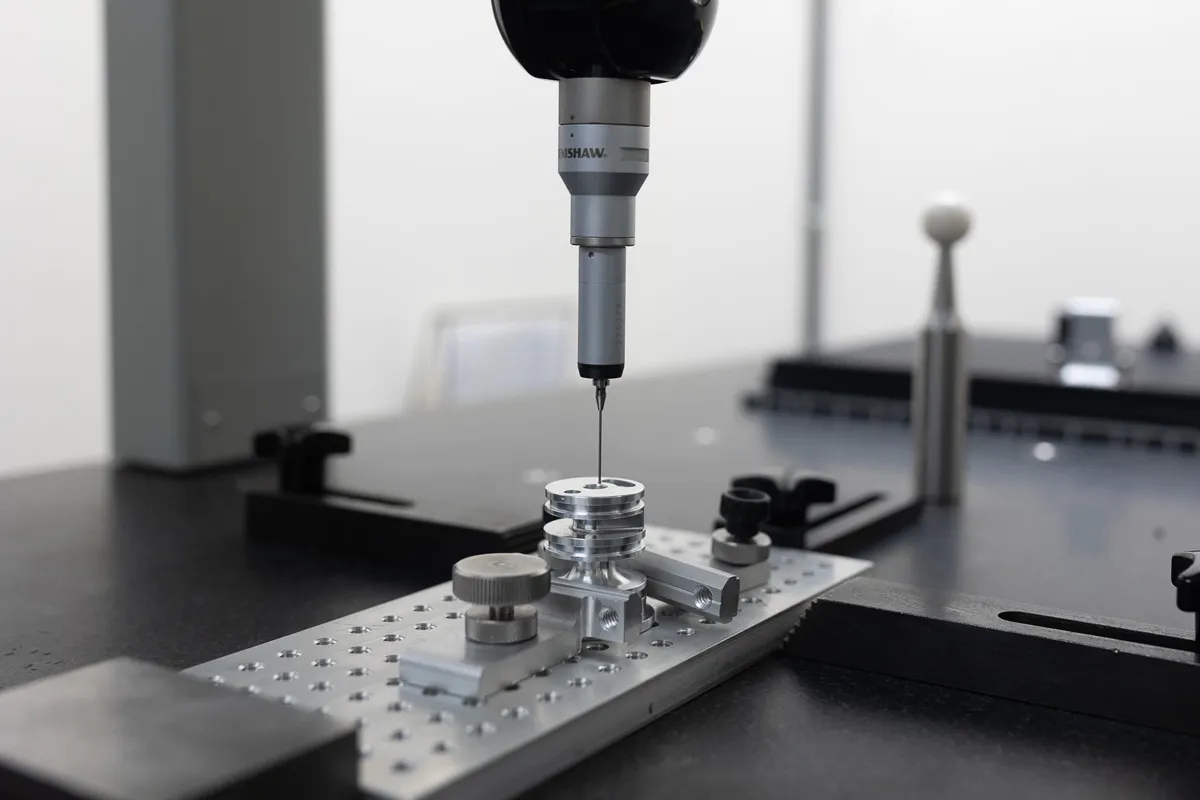

Advanced Metrology

Parts are inspected with CMMs, height gages, optical comparators, and concentricity indicators.

Extreme Precision

We verify dimensions with micrometer-level accuracy to ensure absolute precision.

Equipment List

The highly experienced team at Extreme Precision operates state-of-the-art equipment and metrology tools to achieve tolerances as tight as ±0.0001 inches over lengths up to 12 inches. Using CMMs, optical comparators, and specialized metrology tools, we deliver and verify high-precision components for critical industries. Explore our equipment below:

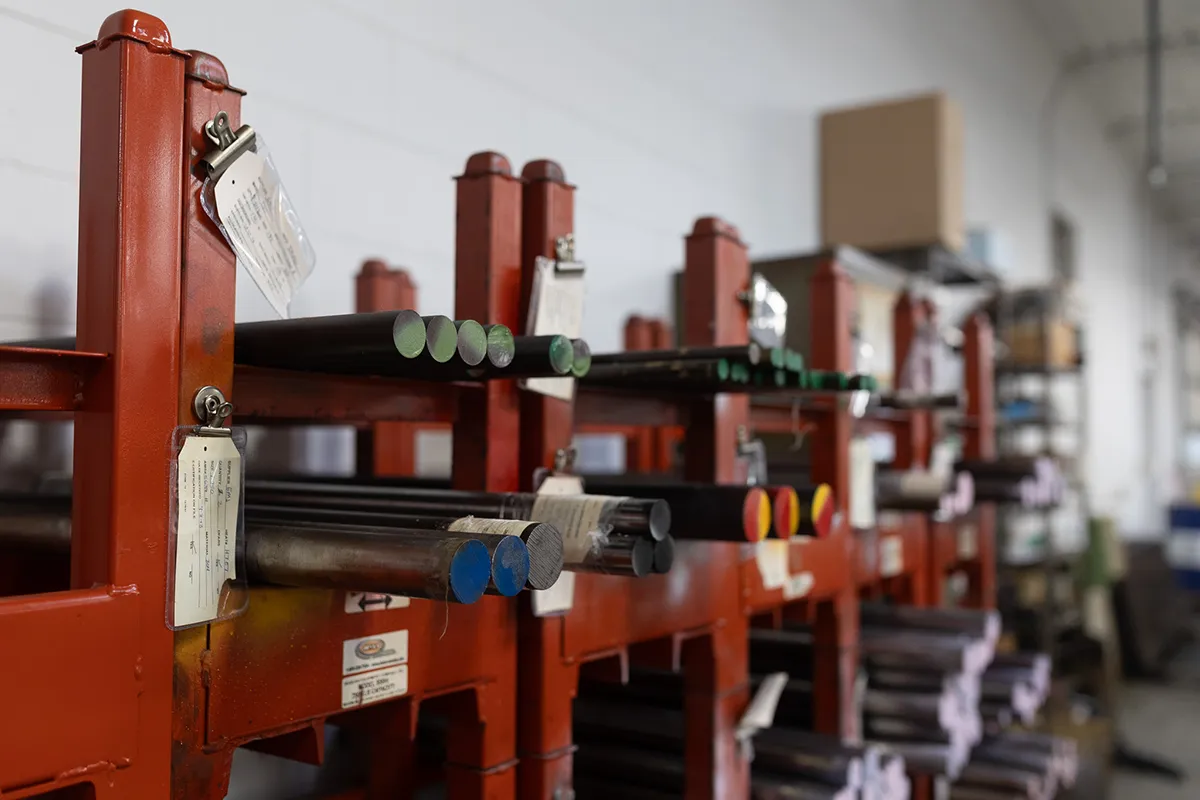

Common Materials

We manufacture precision components from a wide range of durable, high-performance metals. Frequently used materials include:

Aircraft Alloy

- 4130

- 4340

- Stellite

Aluminum

- 2011-T3

- 2024-T851

- 6061-T6

- 6061-T651

- 6061-T6511

- 7075-T7351

Carbon Steel

- 1018

- 1141

- 1215

- 12L14

Brass / Bronze

- C36000

- C51000

Nickel Alloy

- 718

- A-286

Stainless Steel

- 303

- 304

- 316

- 321

- 347

- 410

- 416

- 416 HT

- 418 Greek Ascoloy

- 440

- 440C

- 13-8

- 15-5

- 17-4

Request a quote