About

our History

83 Years of PRECISION

Extreme Precision Screw Products was founded in Flint, Michigan, in 1943, when Howard Aseltine carried forward the vision of his late partner J.E. McLucas. What began in a rented shack with a few screw machines quickly grew into a trusted manufacturing partner during World War II, producing precision parts like firing pins for the .50 caliber machine gun. From those humble beginnings, Extreme Precision has proudly remained family-owned for 83 years. Today, brothers Steve and Jeff Blevins carry that tradition forward, honoring the legacy of their father, Mark, and uncle Howard before them.

Customers we served in our earliest days, including Bendix Corporation (now Honeywell Aerospace), continue to trust us today—a testament to our precision and reliability. Rooted in Flint, we remain grounded in integrity and grit, ensuring every part we produce meets the highest standards of American manufacturing. As we grow—welcoming Manson Reamers, Inc. in 2022 and Veit Tool Inc. in 2024—our family’s promise of precision, integrity, and quality is stronger than ever.

Why Choose EXTREME Precision?

Aerospace-Grade Quality & Certifications

Extreme Precision is AS9100-certified and NADCAP accredited, meeting the highest aerospace standards for safety, traceability, and reliability. Clients can trust every part to exceed strict compliance requirements.

Trusted Track Record Since 1943

For 83 years, Extreme Precision has earned the trust of top-tier clients including Honeywell Aerospace and Triumph Actuation Systems. Our reputation is built on reliable results and lasting partnerships.

Extreme Precision Capabilities

With state-of-the-art machinery and advanced inspection technology, Extreme Precision can hold tolerances as tight as ±0.0001 inches. Complex, mission-critical parts are manufactured with precision and consistency.

Quality Guarantee & Commitment

Ultra-Precision

Machining

High-tolerance CNC, milling, and screw machining for complex parts, from prototypes to full production runs.

Sub-Assemblies

& Manufacturing

Build-to-print sub-assemblies and small-batch production, delivering reliable, ready-to-use components.

Passivation &

Quality Inspection

Protective finishing processes paired with rigorous inspections to ensure every part meets exact standards.

The EXTREME Precision Process

Our proven, step-by-step process ensures every project is delivered to spec and on schedule. From the initial consultation to final delivery, this documented approach sets clear expectations, builds trust, and provides a repeatable blueprint for consistent success. The “Precision Process” is outlined in four key stages:

Request a Custom Job

Stage 1

Consultation & Quoting

Every project begins with a detailed consultation to review requirements, including part specifications, tolerances, certifications, materials, and delivery timelines. Based on this information, Extreme Precision provides a comprehensive quote and schedule. This upfront clarity ensures everyone is aligned, eliminating surprises and building trust from the start.

Stage 2

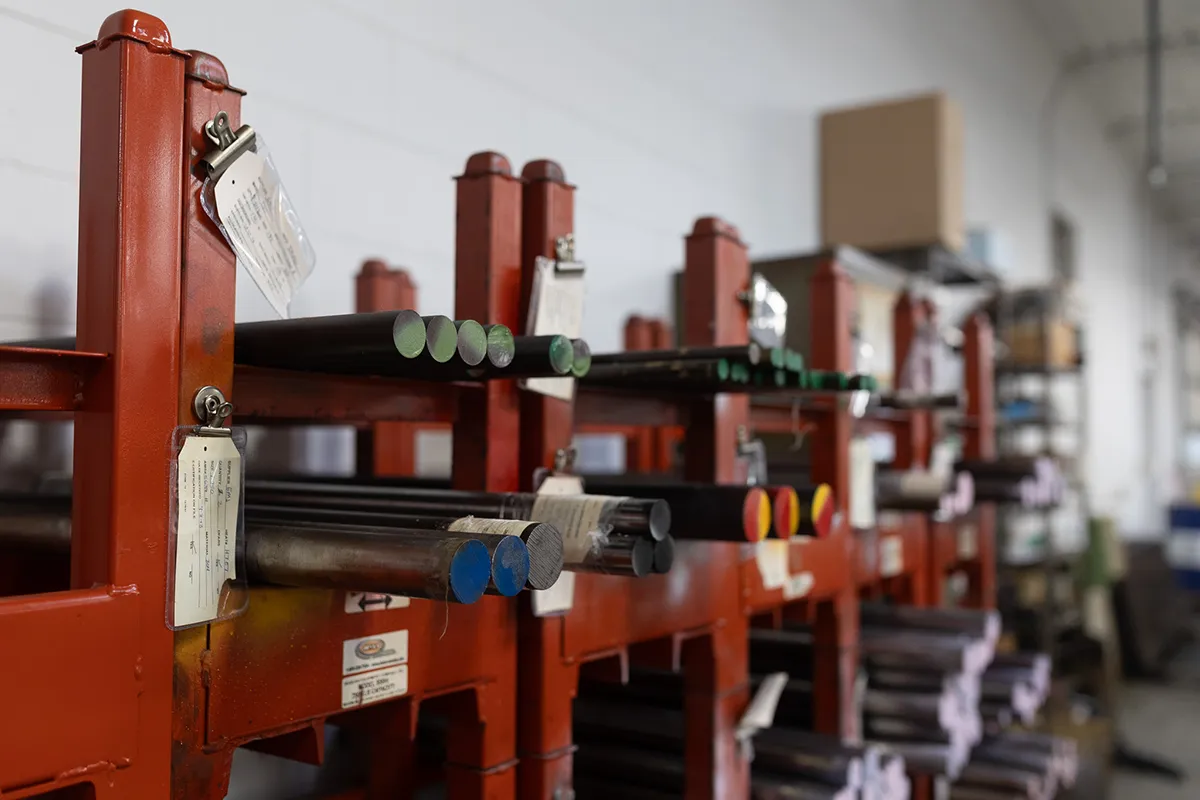

Engineering & Production Planning

Once the quote is approved, our CNC programmers, Quality department, and Operations design the manufacturing plan. This includes selecting machines, tooling, and machining sequences, while sourcing or verifying materials. By carefully scheduling and preparing, we set even the most complex jobs up for success.

Stage 3

Precision Manufacturing & Quality Checks

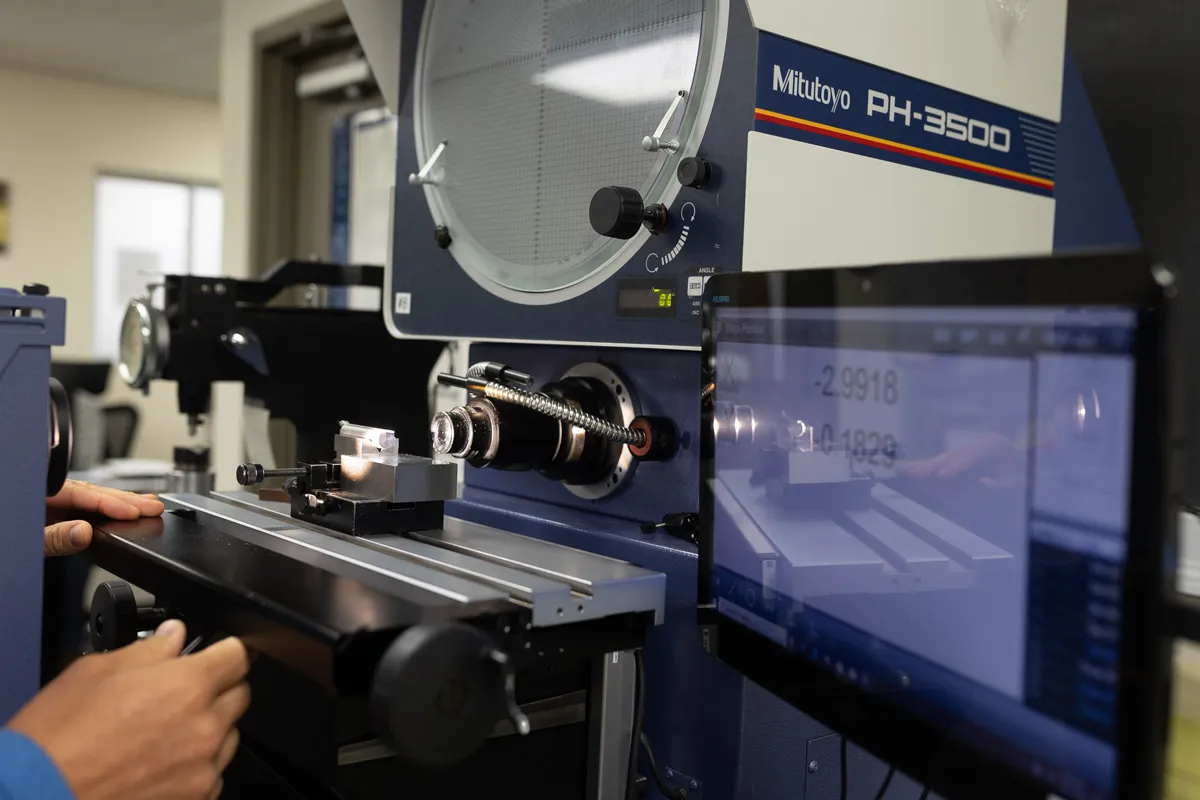

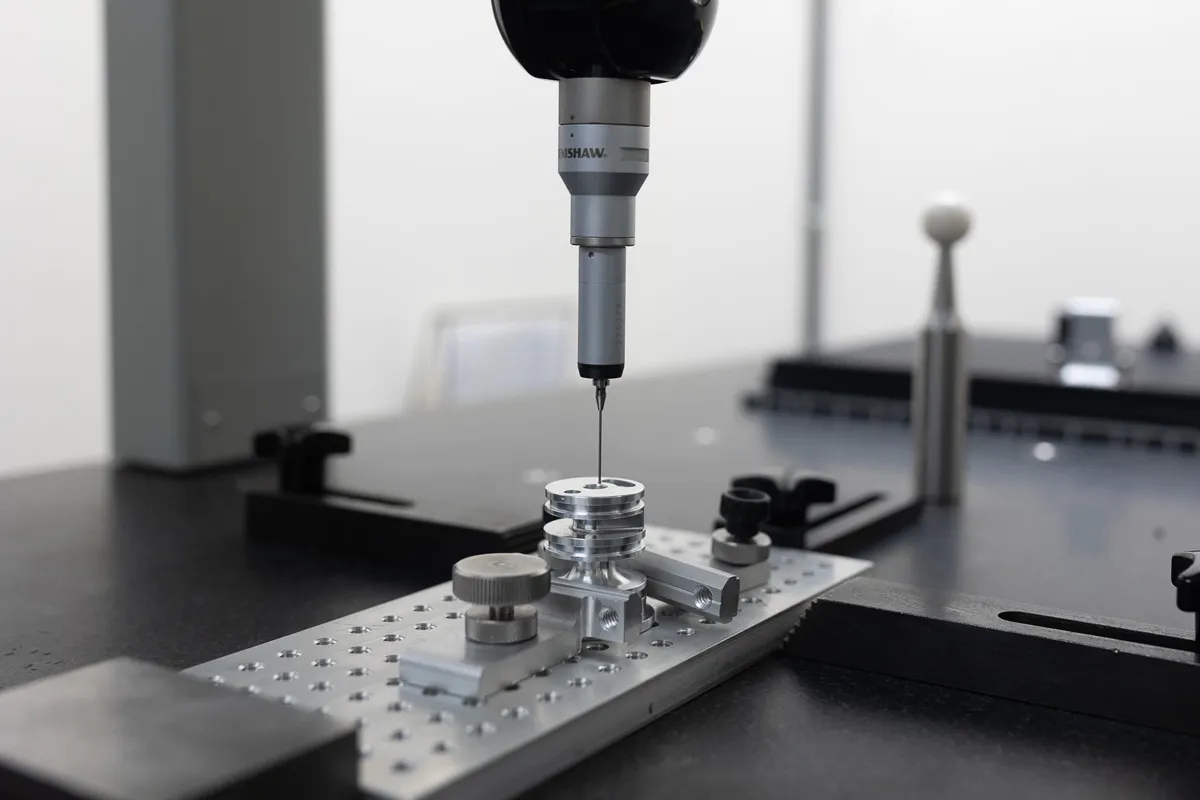

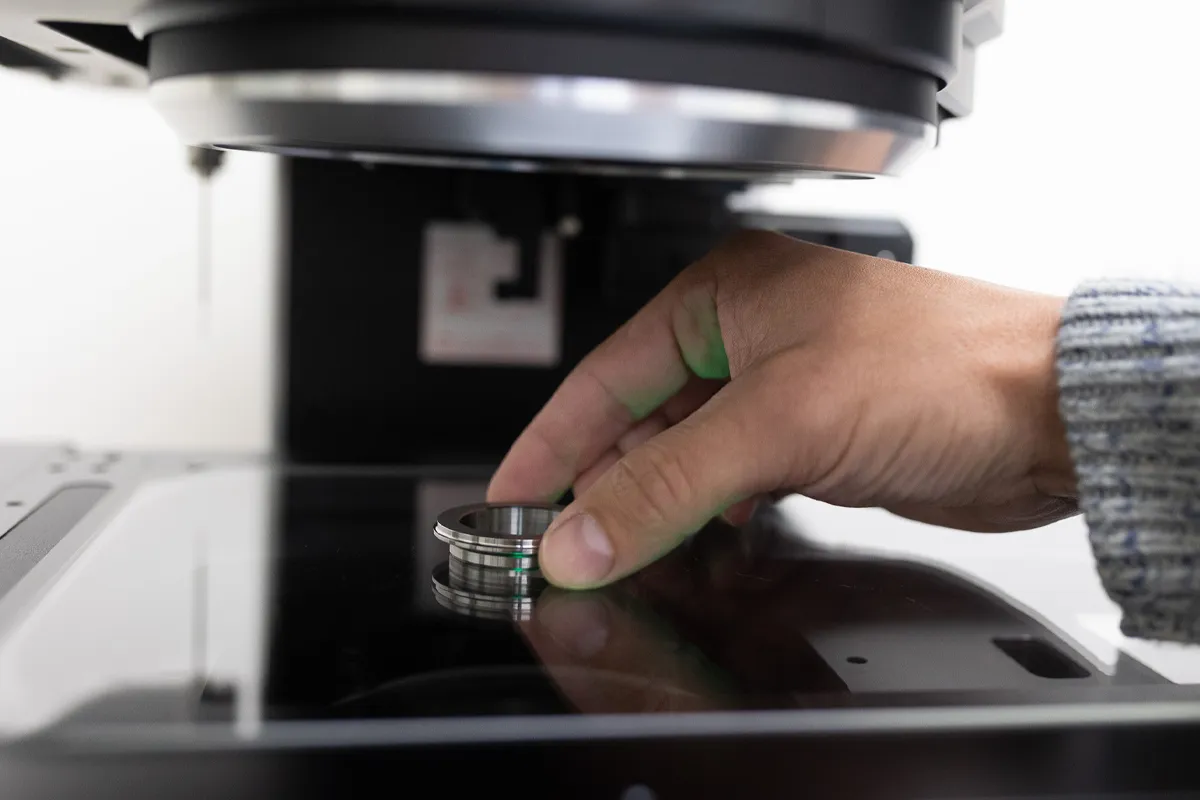

With the plan in place, our skilled machinists bring components to life. In-process inspections verify critical dimensions throughout production, preventing errors before they occur. Using advanced metrology equipment, we confirm accuracy down to ±0.0001 inches, ensuring every part matches the blueprint.

Stage 4

Final Inspection & Delivery

Before shipment, every part undergoes a final quality inspection using our CMM, height gauges, and optical comparators. All required documentation—inspection reports, certifications, and process records—is provided with the order. We then package, ship, and follow up to ensure complete satisfaction.

Meet Our Team

At Extreme Precision, our team brings decades of experience in precision manufacturing, machining, and tooling. Guided by a shared commitment to quality, innovation, and service, they continue to build on the company’s legacy while driving growth across a family of trusted companies.

Steve Blevins

President & Co-Owner

Steve Blevins has been immersed in the manufacturing industry since his youth, gaining hands-on experience while working throughout middle and high school. After earning a business degree, he combined his education with a passion for precision manufacturing, honing leadership skills that drive innovation and growth. As President and Co-Owner of Extreme Precision, Steve is dedicated to delivering exceptional machining and tooling solutions while fostering a culture of continuous improvement and excellence.

Steve takes pride in every aspect of the manufacturing process, from envisioning projects and creating quotes to overseeing the final product’s delivery to customers. His commitment to quality and service has helped establish Extreme Precision as a trusted name in the industry.

Beyond his leadership at Extreme Precision, Steve also serves as Vice President and Co-Owner of both Manson Reamers, Inc. and Veit Tool Inc., contributing his expertise across the family of companies.

In his free time, Steve enjoys staying active, spending quality time with his family, and taking the occasional ski trip out west.

Jeff Blevins

Vice President & Co-Owner

Jeff Blevins has built his career in high-precision manufacturing, developing extensive expertise in producing complex, high-tolerance components. As Vice President and Co-Owner of Extreme Precision, he helps lead the company with a focus on innovation, precision, and maintaining its reputation for excellence.

Throughout his career, Jeff has had the privilege of manufacturing critical components for some of the most advanced aircraft in the U.S. military, contributing to mission-critical defense applications. His leadership and dedication to quality ensure that Extreme Precision continues to deliver exceptional machining solutions to customers across industries.

In addition to his role at Extreme Precision, Jeff also serves as President and Co-Owner of both Manson Reamers, Inc. and Veit Tool Inc., where he continues to champion continuous improvement and technical excellence.

In his free time, Jeff enjoys visiting the gun range, spending quality time with his family, and playing guitar.

Amanda Cornell

Business Development Manager

Amanda Cornell has over a decade of experience in manufacturing, having held key roles at Extreme Precision, including Office Manager and Operations Manager. Now, as Business Development Manager for Extreme Precision, Veit Tool Inc., and Manson Reamers, Inc., she focuses on driving growth and optimizing processes across all three companies.

Amanda earned a Bachelor of Applied Science in Small Business Management and Entrepreneurship from Ferris State University, equipping her with the skills to enhance efficiency and streamline operations. She thrives on problem-solving, finding innovative ways to improve workflows for both the company and its employees.

Outside of work, Amanda enjoys spending time with family and friends, attending sporting events, and working on her family farm.

Brad Patterson

Quality Manager

Brad Patterson brings over thirteen years of quality experience to Extreme Precision, with a background spanning Automotive, Medical, Gearing, and now Aerospace. His career path has included roles as Lead Inspector, CMM Programmer, Platform Quality Engineer, and Quality Engineer before stepping into his current role as Quality Manager here at Extreme Precision.

At Extreme Precision, Brad is dedicated to driving continuous improvement, reducing scrap, and elevating product quality; all while ensuring strict compliance with AS9100 standards. He also serves as Quality Manager for Blevins Screw Products, a family-owned affiliate company, where he applies the same commitment to excellence and innovation.

Outside of work, Brad enjoys time with his family and being outdoors, whether camping, fishing, hunting, or staying active through coaching and sports.

Rayna Bryant-Ott

Office Manager

Rayna Bryant-Ott serves as the Office Manager at Extreme Precision, where she ensures smooth daily operations and provides dependable support to both clients and colleagues. She manages incoming RFQs and purchase orders, oversees the processing of production schedules and inventory, coordinates receipt of incoming material and tooling orders, while also training and supporting users on the company’s manufacturing system. With strong organizational skills, attention to detail, and a commitment to excellence, Rayna provides timely communication and dependable service across all areas of the business.

Outside of work, Rayna enjoys life as an empty nester. She spends her free time traveling, square dancing, attending Bible study, singing in her church choir, and sharing meaningful moments with family and friends.

Request a quote