Industries

our expertise

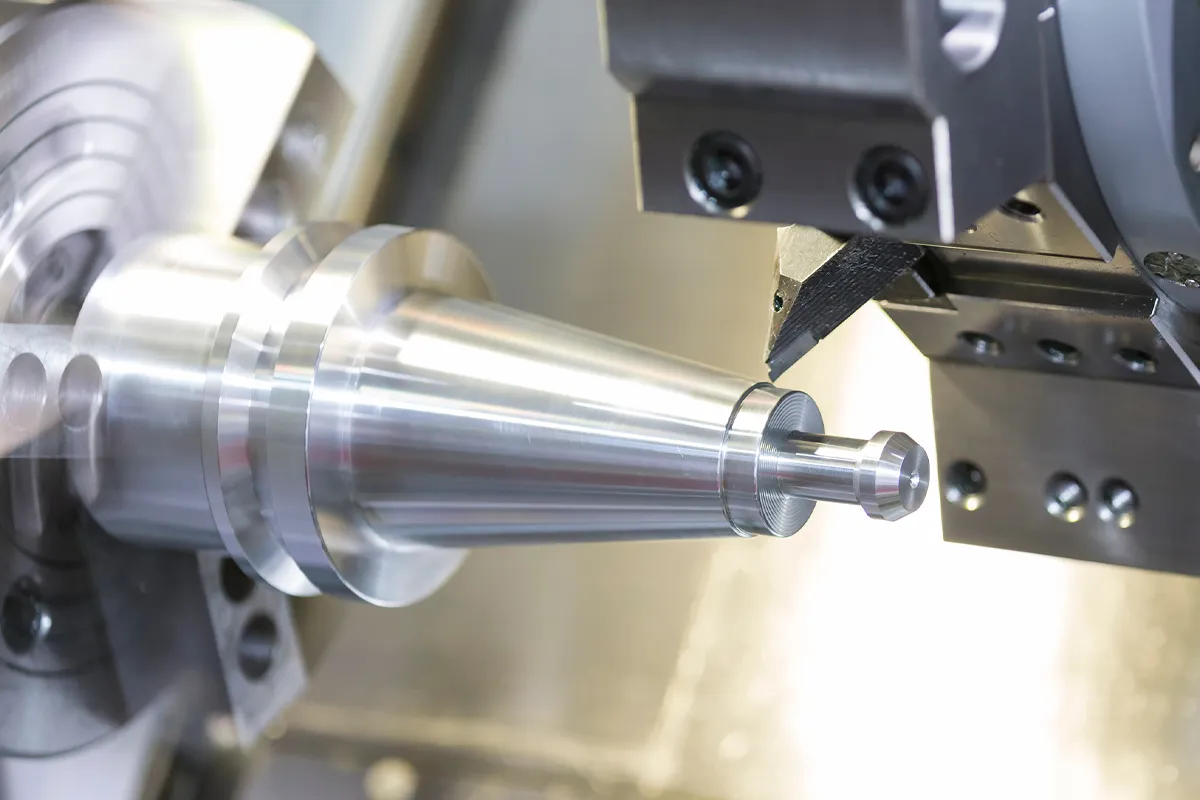

ULTRA-Tight Tolerances & Non-Negotiable QUALITY

For 83 years, Extreme Precision has partnered with industries where precision isn’t optional — it’s mission-critical. Our clients include global OEMs and Tier 1 and Tier 2 suppliers who count on us for uncompromising accuracy, flawless finishes, and assemblies that perform under the highest demands.

We specialize in solving the complex machining challenges that others can’t, ensuring every component meets exact specifications. By focusing only on industries that demand uncompromising quality, we’ve built a reputation as a trusted partner for companies who require nothing less than absolute reliability.

Select an industry below to see how we deliver precision where it matters most.

100%

American Parts & Labor

Request a quote

Industry Leaders Choose EXTREME Precision

Aerospace-Grade Quality & Certifications

Extreme Precision is AS9100-certified and NADCAP accredited, meeting the highest aerospace standards for safety, traceability, and reliability. Clients can trust every part to exceed strict compliance requirements.

Trusted Track Record Since 1943

For 83 years, Extreme Precision has earned the trust of top-tier clients including Honeywell Aerospace and Triumph Actuation Systems. Our reputation is built on reliable results and lasting partnerships.

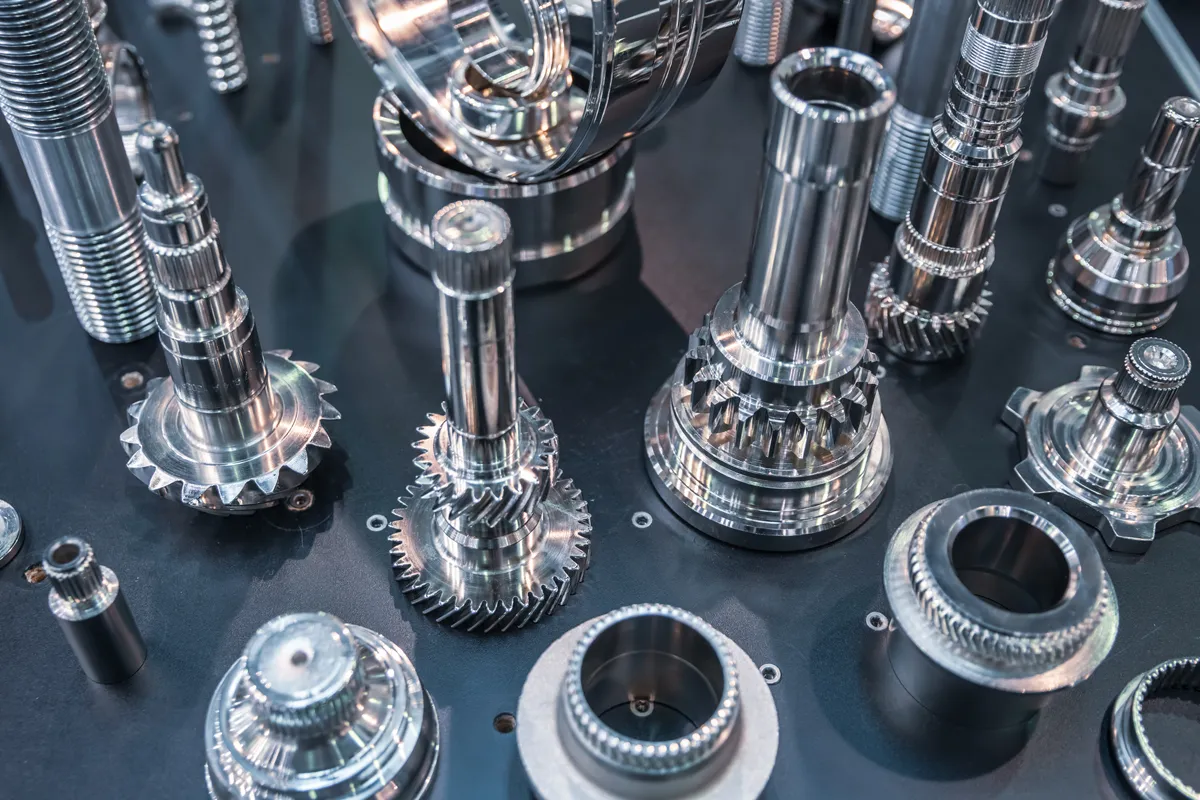

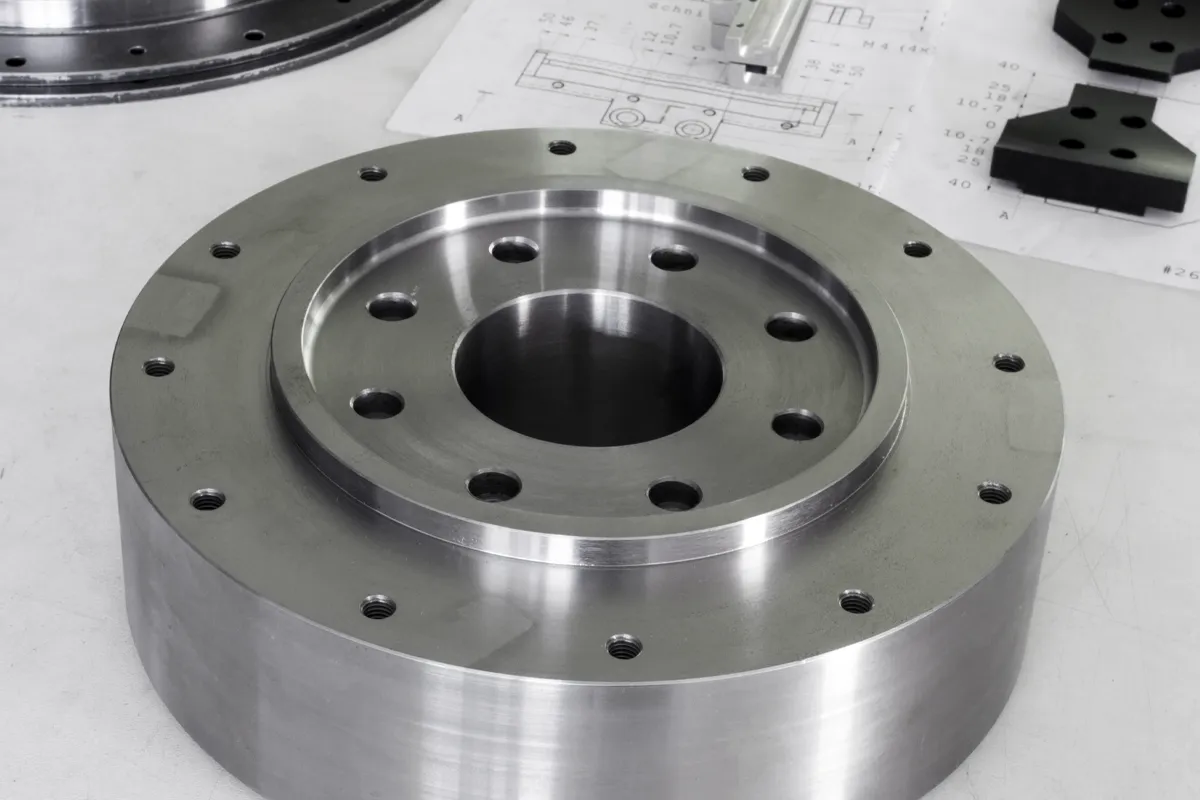

Extreme Precision Capabilities

With state-of-the-art machinery and advanced inspection technology, Extreme Precision can hold tolerances as tight as ±0.0001 inches. Complex, mission-critical parts are manufactured with precision and consistency.

Quality Guarantee & Commitment

Every part is inspected to aerospace-level standards and verified with advanced equipment. If it doesn’t meet your specifications, Extreme Precision will make it right—no questions asked. Read Quality Quarantee Details >

Ultra-Precision

Machining

High-tolerance CNC, milling, and screw machining for complex parts, from prototypes to full production runs.

Sub-Assemblies

& Manufacturing

Build-to-print sub-assemblies and small-batch production, delivering reliable, ready-to-use components.

Passivation &

Quality Inspection

Protective finishing processes paired with rigorous inspections to ensure every part meets exact standards.

Aerospace

Aerospace partners rely on us for components that meet AS9100 standards. We produce flight-critical parts and subassemblies trusted by industry-leading manufacturers.

Aerospace Clients

Automotive

From prototypes to small-batch production, we supply components for drivetrains, safety systems, and specialty automotive applications rooted in our Flint heritage.

Automotive Clients

Defense

Defense Clients

Firearms

Our story began in WWII making firing pins for the .50 caliber machine gun. Today, we continue producing firearm components trusted by OEMs and custom makers.

Firearms Clients

Medical

With capabilities ranging from high-precision medical components like surgical handles to specialized cutting tools, such as delicate instruments like ophthalmic cutters, components are made to our exacting, reliable quality standards.

Medical Clients

Specialty

We also serve a variety of manufacturers, OEMs, and Tier 1 and Tier 2 suppliers representing other industries that demand precision, quality, and reliable solutions.

Our Clients