Sorry, no content matched your criteria.

Extreme Precision Screw Products

Quality parts manufacturing.

Our Companies

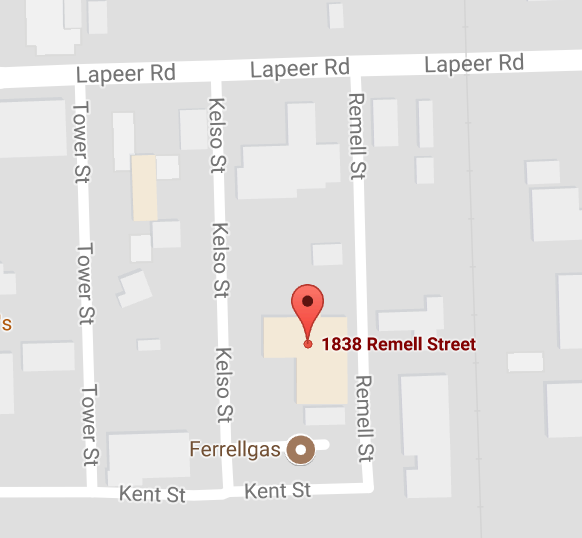

Our Location

1838 Remell Street | Flint, MI 48503

Contact & Hours

810-744-1980

810-744-1821

Monday - Friday: 6AM - 3PM

What We Believe

“Excellence is never an accident;

it is the result of high intention,

sincere effort, intelligent direction,

skillful execution and the vision

to see obstacles as opportunities.”

~Anonymous

it is the result of high intention,

sincere effort, intelligent direction,

skillful execution and the vision

to see obstacles as opportunities.”

~Anonymous